Prototyping is an essential aspect of the development of parts for a variety of businesses. As a leading Cleveland tool and die company, Valco Valley Tool & Die, Inc. is proud to be able to put our considerable experience to work in producing custom metal components. We work closely with all of our clients, ensuring the best quality product, with the best solution for your blueprints.

With innovative designs being created daily, we know that you may have to try a few sizes before the shoe fits perfectly. Our prototyping department will help you design and craft the vital parts you need for products. Let us help you discover what will work best for your applications.

Our Custom Fasteners and Prototype Metal Stamping

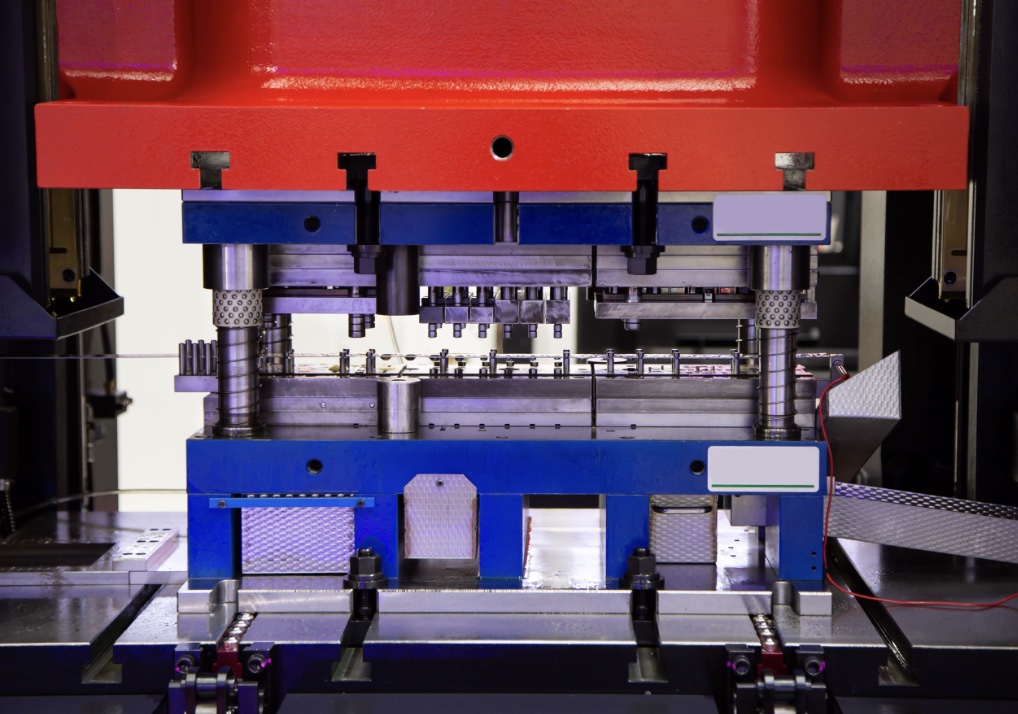

Equipped with large capacity presses, our Metal Stamping Department enables us to produce a large quantity and variety of metal stampings and custom fasteners for your products. We work with the needs of our customers, meaning we can run small or large productions.

Here are a few key products that we’ve crafted for specialized purposes over the years:

At Valco, we know how to customize small, stamped products for a wide array of industries. One of the best features of our trusted services includes our ability to prototype for our clients. This includes services from any area of our company, from the CNC Turning Center to our four-slide department. And our prototypes can be the right fit for many industries, including:

- Product engineering

- Healthcare

- Construction

- Retail

- Advertising displays

- Office

In all the companies we work with, Valco has the capabilities to create essential prototype metal stampings for innovative products. We craft endless solutions no matter the industry or company need.

Defining the Process for Prototype Manufacturing

When going through the process of prototype stamping, we make sure to listen to your needs so we can execute your desires and ensure you’re satisfied with the final product.

Here is an overview of the prototype metal stamping process:

- Discuss design preferences – We will determine any dimensions and features you need in your parts, and we will work them into the design

- Select materials – We will select the right material for your application based on preferences like strength, corrosion resistance, and more

- Create the prototype – We will create a prototype of the piece using custom tool and die work

- Test and analyze – Next, you will test the prototype to make sure it fits your application and performs to your standards

- Refine – If necessary, we will revise the design and create a new prototype to make sure you get the right fit

- Produce in desired quantity – Once you are happy with the product, we will create it in the quantity of your liking

Benefits of Working with a Prototype Metal Stamping Manufacturer

The team at Valco knows that no two applications are the same, so we want to provide a unique solution for your unique project. Our prototype manufacturing team will help you achieve the best possible solution, and advantages we supply include:

- Expertise – When you work with our team of prototype stamping experts, you will discover how each of our decisions is backed by a well-defined explanation and over 50 years of experience

- Quality control – We hold the ISO 9001:2015 with design certification that ensures that our processes conform to a quality management system, meaning your pieces will meet your specifications and quality standards

- Flexibility – Since our prototype metal stamping department has a wide variety of tools and dies available, we are able to create custom-designed pieces that fit your unique applications

From our work in creating diverse snap buttons to our abilities in prototype manufacturing, we pride ourselves on our history of quality products, service, and performance.

Additionally, Valco proudly manufactures all of our products in the USA, which means you can expect quality and quick shipping since our processes aren’t outsourced.

Some FAQs About Prototyping

Here are a few frequently asked questions we get along with answers to give you a little more insight into the process of prototype stamping.

How does prototyping help with design?

Using a prototype part allows you to see the fit, form, and function to ensure that the pieces will fit seamlessly into your current application. The prototype will also expose any design flaws or inconsistencies that will cause problems in the future.

Will prototype manufacturing be costly?

The costs associated with prototyping are certainly offset by what you’ll save from limiting the need for costly modifications or repurchases later on. Trust us when we say it is better to know for sure than it is to guess and face downtime from parts that do not fit properly!

How many iterations of prototypes are typically needed?

The number of iterations required will depend on the design complexity and the application itself. We will work with you through this process to create the perfect part that is designed specifically for your unique application.

The Services We Provide Outside of Prototype Stamping

In addition to offering metal stamping, progressive die stamping, and our signature line of snap buttons, we can additionally provide services incorporating several different departments to create custom metal parts for your products.

CNC Turning

At Valco, our creative prototype manufacturing provides the best samples for companies before you even decide to use us as your metal parts manufacturer. Some of our CNC turning capabilities include:

- Specialty screws

- Fittings

- Pins

- Specialty nuts

- Caps

- Connectors

- Shafts

Slide Forming

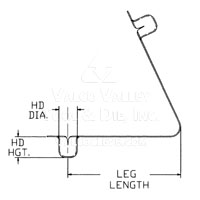

Four-sliding products we carry include custom-shaped snap buttons. We are very proud to be able to customize these parts to your prints. Some common slide stamping products include:

- Cord clips

- Mining drill bit clips and snap buttons

- Specialty application fasteners

Get a Head Start on Prototype Stampings and Contact Us Today!

If you’re starting a project and are in need of prototypes be sure to reach out to Valco today. With over 50 years of experience under our belt, we’re equipped to be your go-to prototype manufacturing company. Our dedicated team is ready to get to work and get creative.